Molding and Casting

Assignments:

Group assignment:

⚡ Review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them.

Extra credit:try other molding and casting processes.

Individual assignment:

⚡ Design a mold around the stock and tooling that you'll be using, mill it (rough cut + three-axis finish cut) and use it to cast parts.

Extra credit: use more then two mold parts.

During week #12 we been doing funny things with molds and other stuff related to that.

At the beginning I have no idea of what I could do with this technique (I've had never tried exploring this "mold world"), so I thought in my Final Project, and I could make the device button by a molding and casting process.

Group Assigments

The materials

Percentage of components used

-

Based on a vase as measure (100%), we can said that you need to mix the quantities mentioned below

- Component A - 40%

- Component B - 40%

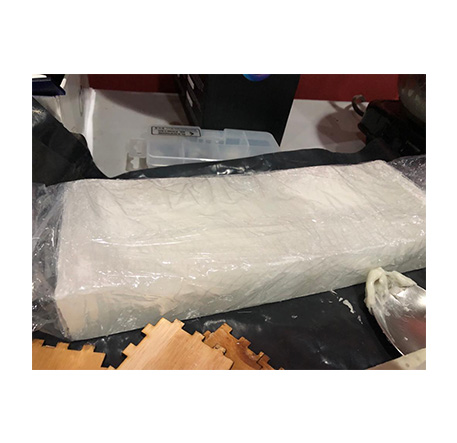

If you don't have a mold as I had, melt paraffin into a container for machining then